- Home

- About Us

- Products

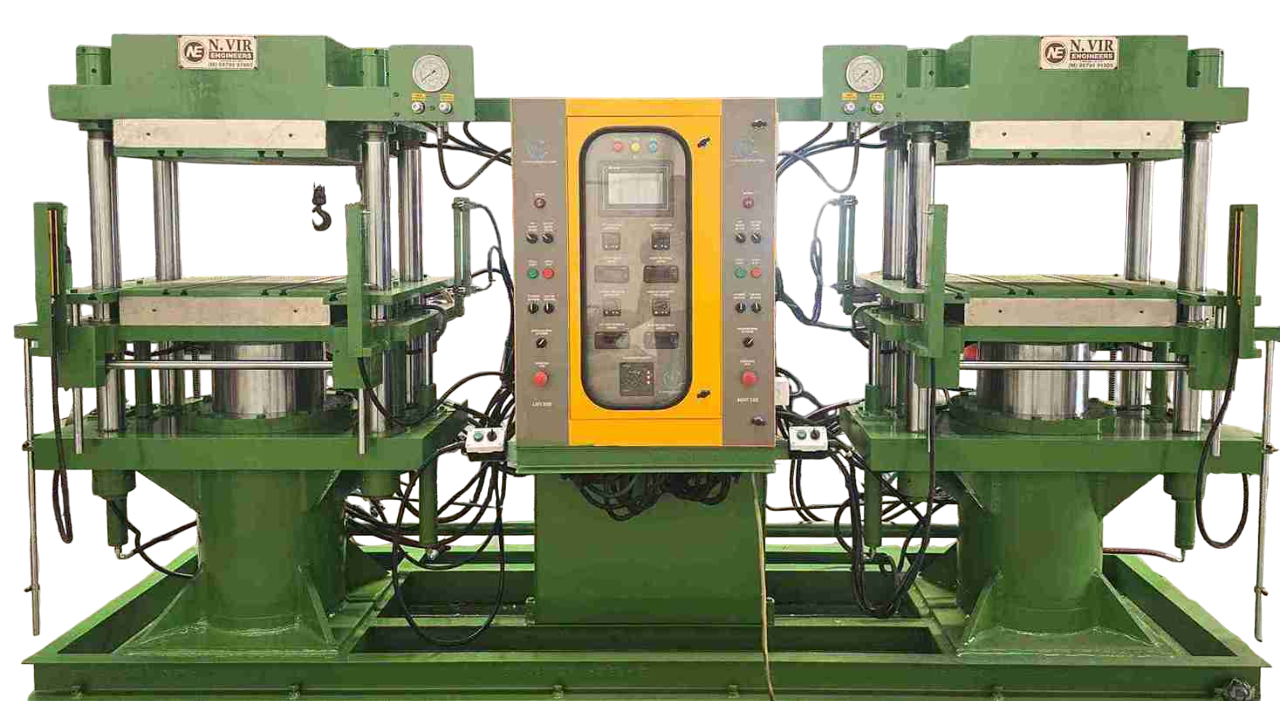

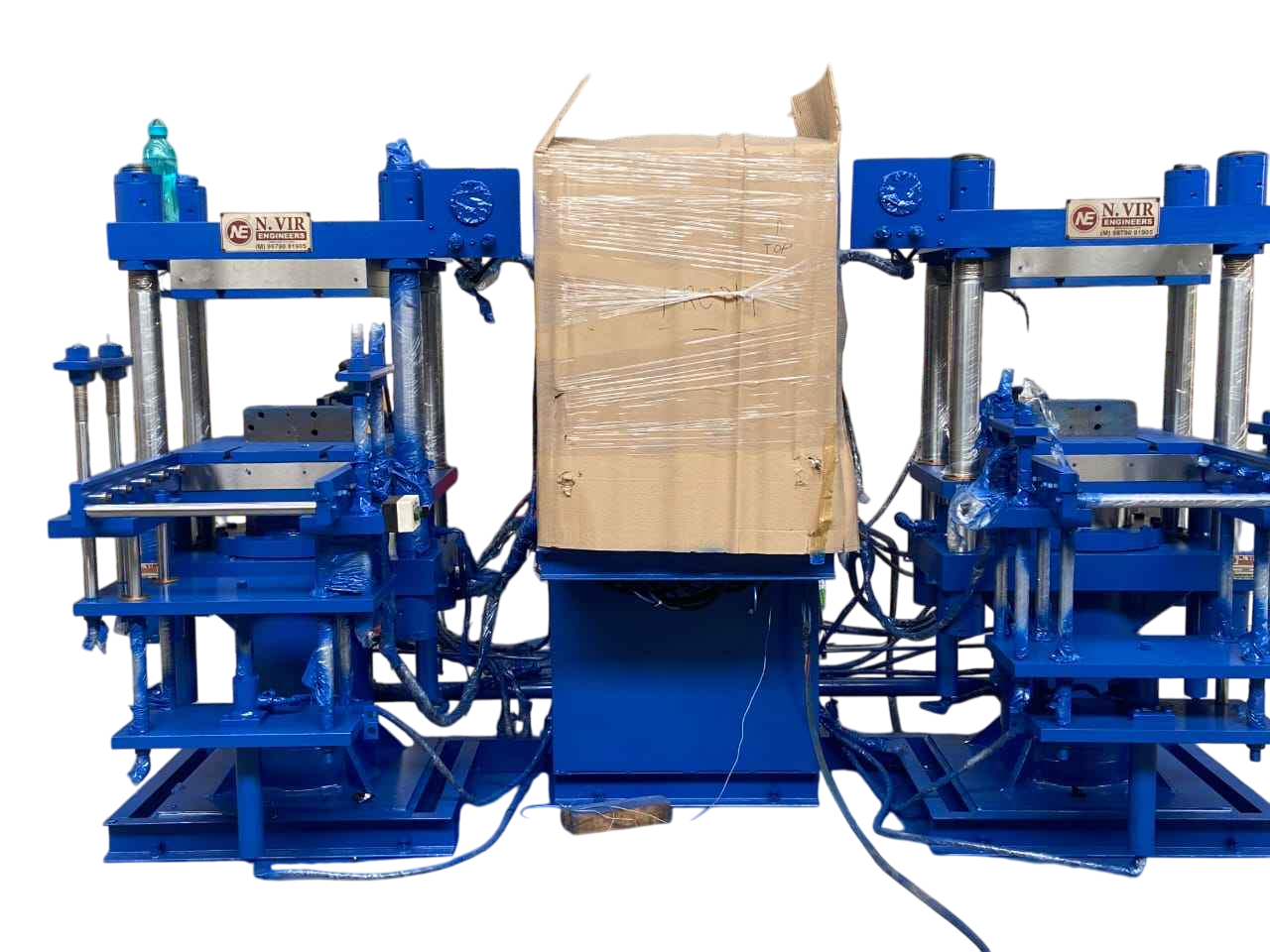

- [H] Type Hydraulic Rubber Molding Press 100 to 1500 Ton

- Hydraulic Rubber Molding Press Three Die Fully Automation Machine Platan size is 20×20 = 200 Ton

- Hydraulic Rubber Molding Press Fully Automation Machine Platan size is Platan size 28×28 = 300 Ton

- Hydraulic Rubber Molding Press Fully Automation Machine Platan size 16×16 = 100 Ton

- Hydraulic Rubber Molding Press Fully Automation Machine Platan size is = 20×20 = 150 Ton

- Hydraulic Rubber Moulding Press Machine Platan size 16×16 = 100 Ton

- Hydraulic Rubber Molding Press Machine Platan size is 12×12 = 40 Ton

- Hydraulic Rubber Corelifter Fully Automation Machine Platan size is 25×25 = 200 Ton

- Gallery

- Contact

![[H] Type Hydraulic Rubber Molding Presss We manufacture [H] Type Hydraulic Molding Press Machines with a solid MS plate window-type press body. The machine features window machining for precise platen leveling and heavy welding fabrication, finished with a coat of paint. We offer this [H] Type Hydraulic Molding Press Machine in capacities ranging from 100 to 1500 tons, tailored to the client’s platen size requirements. [H] Type Hydraulic Rubber Molding Presss](https://nvirhydraulic.com/wp-content/uploads/elementor/thumbs/H-Type-Hydraulic-Rubber-Molding-Presss-1-qytcxa80hauu1grupyglfzcdstwwugs884dd4hjvrc.png)