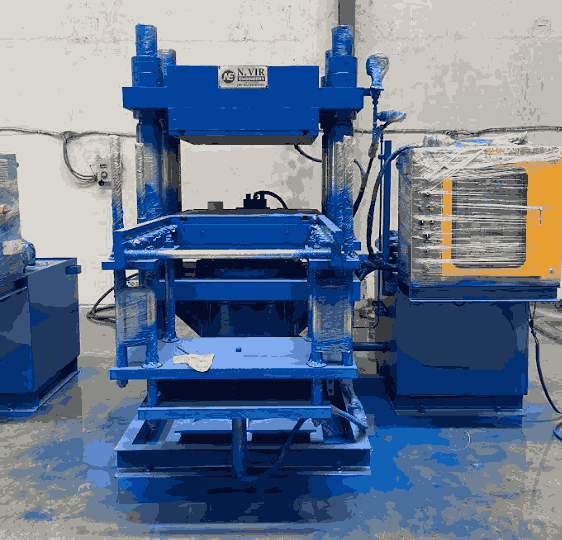

Hydraulic Rubber Molding Press Fully Automation Machine Platan size is Platan size 28×28 = 300 Ton

A Hydraulic Rubber Moulding Press Fully Automation Machine is an advanced machine designed to manufacture rubber products using hydraulic pressure and fully automated processes. It uses hydraulic force to mold rubber materials into specific shapes while applying the necessary heat for curing (vulcanization) and shaping. The machine operates with minimal human intervention, ensuring high efficiency, accuracy, and uniformity in production.

Fully Automated: The entire process (loading, molding, curing, and unloading) is automated, reducing human labor and improving production speed.

Hydraulic Pressure: Uses hydraulic force to press rubber into molds, ensuring strong and uniform product formation.

Versatile Molding: Suitable for a wide range of rubber molding applications across various industries.

| Industry | Applications |

|---|---|

| Automotive Industry | – Rubber seals and gaskets for engines, doors, and windows |

| – Bushings, vibration dampers, and other automotive rubber components | |

| – Rubber mats, floorings, and air intake seals | |

| Electrical Industry | – Rubber insulators and electrical connectors |

| – Gaskets and seals for electrical equipment | |

| Medical Equipment | – Gaskets, seals, and rubber parts for medical devices (e.g., valves, tubes) |

| – Molding of silicone rubber parts for surgical and diagnostic equipment | |

| Consumer Goods | – Rubber seals for appliances (washing machines, refrigerators, etc.) |

| – Toys and rubber products for household use | |

| Industrial Components | – O-rings, grommets, seals, and gaskets for industrial machinery |

| – Rubber parts for hydraulic and pneumatic systems | |

| Construction Industry | – Rubber seals for windows, doors, and construction machinery |

| – Vibration dampers and soundproofing materials for buildings | |

| Aerospace | – Rubber gaskets, seals, and vibration isolators for aerospace components |

| Sports and Recreation | – Molding of rubber parts for sports equipment (e.g., balls, grips) |

| Specification | Details |

|---|---|

| Platen Size | 28″ × 28″ (711 mm × 711 mm) |

| Pressing Force | 300 Tons |

| Molding Process | Compression Molding, Transfer Molding, or Injection Molding |

| Hydraulic Pressure | Varies based on material but typically 10–30 MPa |

| Heating Method | Electric heating or oil heating system |

| Temperature Control Range | 100°C to 200°C |

| Automation | Fully Automated with PLC controls |

| Cycle Time | 5–20 minutes (depending on material and part complexity) |

| Power Supply | Typically 3-phase, 50/60 Hz, 380V or 440V |

| Control System | PLC with touchscreen interface |

| Materials Processed | Natural Rubber, Synthetic Rubber, Silicone, EPDM, etc. |

| Advantages | Details |

|---|---|

| High Production Efficiency | The press works quickly and continuously for mass production. |

| Consistent Quality | Fully automated system ensures uniform quality of molded parts. |

| Energy-Efficient | Optimized hydraulic systems for lower energy consumption. |

| Versatility | Can mold a variety of rubber materials and products. |

| Precision | High-pressure control for precise shaping and molding. |

| Customizable | The press can be customized to different platen sizes or forces. |

| Reduced Labor Costs | Automation reduces the need for manual intervention. |

| Safety | Hydraulic systems and automated controls improve operational safety. |

| Low Maintenance | Advanced hydraulic systems require minimal maintenance. |